| CCS | Croscarmellose Sodium |

|---|---|

| Grades | |

| CAS NO | 74811-65-7 |

| HS Code | 29420090 |

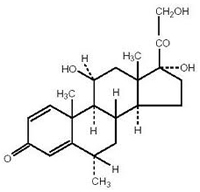

| Molecular Formula | C2H4O3·xNa·x |

| Applications | A cellulose-based superdisintegrant, providing excellent results in tablet disintegration. Used at a level of 1 - 4 % only, it is one of the most efficient superdisintegrants in pharmaceutical technology. It can be used in all tableting processes, good for medium soluble actives. |

| Packing Type | 25 Kgs Corrugated boxes / Fiber Drum |

| STANDARDS | SPECIFICATION | REFERENCE |

|---|---|---|

| Particle size distribution (By Malvern) | ||

| D(v,0.1) | NMT 25 µm | In house method |

| D(v,0.5) | 25-55 µm | |

| D(v,0.9) | NLT 60 µm | |

| PHARMACOPOEIAL TEST ITEMS | SPECIFICATION | REFERENCE |

| Loss on drying | NMT 10.0% | Ph. Eur., NF, JP |

| pH | 5.0 - 7.0 | Ph. Eur., NF, JP |

| Residue on Ethanol | max. 0.5% | In house method |

| The raw materials, manufacturing process and product do not contain any of the solvents listed in Residual Solvents (Ph. Eur. <5.4>, USP<467>) except for ethanol limited to < 0.5% | ||

Croscarmellose sodium is an internally cross-linked sodium carboxymethylcellulose for use as a superdisintegrant in pharmaceutical formulations.[1]

Croscarmellose sodium, or sodium CMC, is a cross-linked polymer of carboxymethylcellulose sodium. It appears as white, fibrous, free-flowing powder.

Disintegrants facilitate the breakup of a tablet in the intestinal tract after oral administration. Cross-linking allows enhanced bioavailability of the drug through superior drug dissolution. Without a disintegrant, tablets may not dissolve appropriately and may effect the amount of active ingredient absorbed, thereby decreasing effectiveness

Croscarmellose sodium is used in oral pharmaceutical formulations as a disintegrant for Capsules, Tablets and Granules. In tablet formulations, Croscarmellose sodium may be used in both direct-compression and wet-granulation processes. When used in wet granulations the Croscarmellose sodium is best added in both the wet and dry stages of the process (intra- and extra granularly) so that the wicking and swelling ability of the disintegrant is best utilized.

|

Your message was sent successfully! I will be in touch as soon as I can.

Something went wrong, try refreshing and submitting the form again.

|